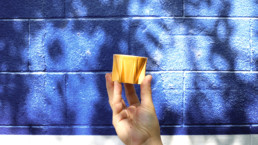

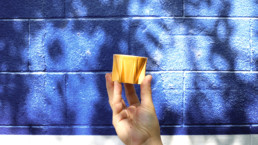

OGIVE

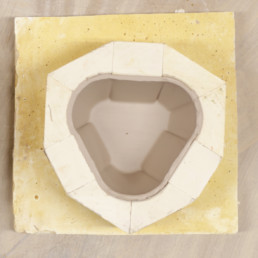

Ogive is a project Charlotte started few years ago with the idea of focusing on the handle: how to include the handle within the shape of the cup itself and still protect the hand from the heat? After several attempts, Charlotte ended up with this architectural model firmly sitting on multiple fins. We both loved the shape but honestly it was a nightmare to mould…

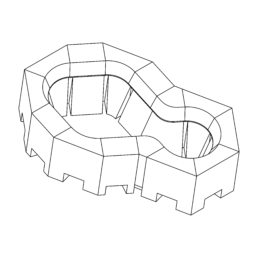

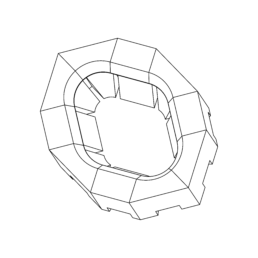

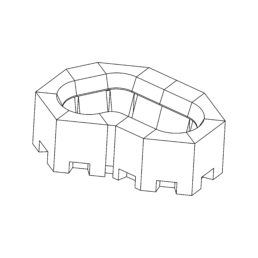

Naturally, we started to think more about the moulding process. We were stuck with the fact that each fin represents a part of the mould, which means that for a simple cup we were sometimes counting thirteen different parts. That obstacle led us to the idea of modular moulds. As we were slicing our mould in dozens of parts, we decided to go further and create different modules to create various shapes. Thanks to this, Ogive is no longer only a cup collection but it turned into an experimentation of containers shapes.

First, we 3D print the mould part in ABS with a fine resolution. Afterwards, we create a master mould of this printed shape, this allow us to rapidly create a lot of parts. Corner parts have an angle of 60°, on the basic shapes such as cercle, triangle or hexagon, the mould is locking itslef once the rubber band tighten it. Thanks to this, we don’t need male/female slots to position our parts.